A factory can have the best raw material. The best workforce. Even the best production plan. But if the cutting tools are dull, damaged, or poorly ground… everything slows down. Output drops. Quality drops. And suddenly, the “small” grinding task becomes a big production headache. That’s exactly why the cutter grinder machine holds so much importance in industrial grinding work.

Because it’s not just a machine that sharpens tools. It’s a machine that restores precision. It brings back cutting accuracy. It saves expensive tooling from being discarded too early. And honestly, it keeps your entire machining ecosystem alive. If you’re a business owner, plant manager, production engineer, or maintenance head, you already know the truth—tool grinding is not optional. It’s the backbone of consistent machining. And when you choose the right cutter grinder setup, you stop fighting tool problems every week.

This is where Ekta Industries stands strong. As a trusted Cutter Grinder Machine Manufacturer, we focus on machines that support real industrial needs—stable grinding, practical operation, and long-term performance. And if you’re searching for a reliable Cutter Grinder Machine Manufacturer In Gujarat or a proven Cutter Grinder Machine Manufacturer In India, this guide will give you clarity without confusion.

Understanding Industrial Grinding Work

Industrial grinding work is not a “support activity.” It directly impacts production quality. Grinding is used to sharpen, shape, and finish cutting tools and components. In most manufacturing plants, grinding plays a key role in maintaining cutting edges, improving tool geometry, and supporting high-accuracy machining operations. A tool that’s properly ground cuts cleaner. It reduces friction. It gives better surface finish. It produces consistent dimensions. And it reduces load on the machine.

But when grinding is poor, the opposite happens. You get rough cuts. You get overheating. You get tool breakage. You get rework. And in industries where accuracy matters, rework becomes a silent cost monster. This is why the cutter grinder machine is so important. It gives manufacturers control over their tooling quality, instead of depending on external grinding services or replacing tools too frequently.

What is a Cutter Grinder Machine?

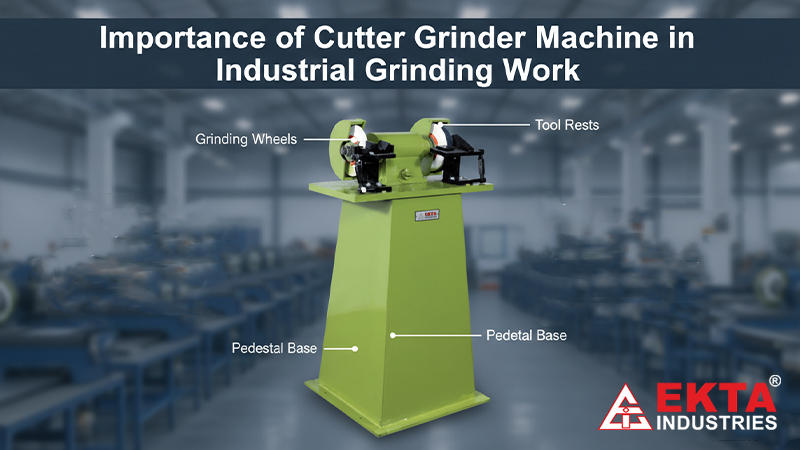

A cutter grinder machine is designed to grind and sharpen cutting tools such as milling cutters, end mills, and other industrial cutters. It helps restore the cutting edge, correct tool angles, and improve tool life. In simple words: it brings your tools back to working condition.

Instead of throwing away expensive cutters, industries use a cutter grinder machine to recondition them. That’s not just smart. It’s necessary in modern production. And when you buy from Ekta Industries, you’re not just buying a grinder. You’re buying a tool-management solution.

Why Cutter Grinding Matters More Than Most People Think

Here’s the thing: many manufacturers focus heavily on CNC machines, lathes, milling machines, and automation. Grinding is often treated as “maintenance work.” But cutter grinding is a productivity driver.

Because tool sharpness directly controls:

- Cutting accuracy

- Surface finish quality

- Cycle time stability

- Power consumption during machining

- Tool life and breakage risk

So, when your cutters are sharp and properly ground, your machines run smoother. When cutters are dull, even the best CNC struggles. This is where a cutter grinder machine becomes a hidden hero in industrial grinding work.

The Real Importance of Cutter Grinder Machine in Industrial Grinding Work

Tool Life Improvement That Reduces Cost: Industrial cutters are not cheap. And replacing them too often creates continuous expense. A cutter grinder machine allows industries to regrind and reuse cutters multiple times. That means your tool inventory lasts longer, and your cost per part reduces over time. This benefit is especially valuable in high-volume manufacturing where cutters wear fast. Many companies don’t realize how much they spend on tooling until they calculate it monthly. Then the reality hits. Hard.

Better Machining Accuracy and Consistency: When a cutter is dull or improperly shaped, it creates variations in machining. One batch looks fine; the next batch goes slightly out of tolerance. And then you start chasing the problem. Grinding restores the correct geometry. It helps maintain consistent cutting angles. And it supports stable machining accuracy. This is critical in industries where parts must match exact specifications, not “almost correct.”

Reduced Machine Load and Less Tool Breakage: A sharp cutter cuts smoothly. A dull cutter forces the machine to work harder. This increases load on the spindle, increases vibration, increases heat, and increases chances of tool breakage. Tool breakage isn’t just a tool loss. It can damage workpieces. It can damage fixtures. Sometimes it can even damage the machine. A cutter grinder machine helps prevent that by keeping tools in proper condition.

Faster Production with Less Rework: When cutters are properly ground, they cut cleaner. This improves surface finish and reduces dimensional errors. That means less rework. Less polishing. Less rejection. And less rejection means smoother production flow. It’s simple but powerful.

In-House Grinding Control; Many factories send cutters outside for sharpening. That’s fine… until you face delays. Or inconsistent quality. Or urgent production requirements. Having an in-house cutter grinder machine gives you control. You decide when to sharpen. You decide the quality. You decide the tool schedule. This independence becomes extremely valuable for manufacturers running tight deadlines.

Why Industries Across India Depend on Cutter Grinder Machines

The demand for accurate machining is rising across India. Industries like automotive components, engineering workshops, tool rooms, and general manufacturing all depend on sharp cutters. And as production competition increases, companies can’t afford slow machining or tool wastage. That’s why the role of a Cutter Grinder Machine Manufacturer In India is becoming more important. Industries want reliable machines that support daily grinding work, not machines that need constant attention.

This is where Ekta Industries has built trust. Because we understand how Indian manufacturing operates—long shifts, practical requirements, and performance-based decisions.

What Makes a Cutter Grinder Machine Truly Useful in a Factory?

Not all grinder machines provide the same value. A good cutter grinder machine should have stable grinding performance, smooth operation, and the ability to support different cutter types. The machine should help the operator grind tools with control and repeatability. Because in industrial grinding work, repeatability is everything. A cutter that looks sharp but has wrong angles is still a problem. So, the machine must support accurate geometry restoration.

Key Features That Directly Improve Industrial Grinding Work

- Stable Grinding Setup: A stable setup reduces vibration and supports cleaner grinding. When vibration is high, grinding becomes uneven and tool edges get damaged. Industrial grinding requires stability. Always.

- Operator-Friendly Controls: Grinding is skilled work. But the machine should not be overly complicated. A practical cutter grinder machine supports easy operation and smoother adjustment. This reduces training time and reduces operator mistakes. And yes, factories love that.

- Smooth Movement and Precise Adjustments: Grinding requires fine movement control. A machine that allows smooth positioning makes the grinding process more accurate. This improves tool quality and reduces the risk of uneven grinding.

- Strong Build for Industrial Conditions: Industrial environments have dust, heat, and long hours. Machines must be built to handle it.

That’s why manufacturers prefer working with a trusted Cutter Grinder Machine Manufacturer rather than random suppliers.

A Quick Comparison Table: Manual Sharpening vs Cutter Grinder Machine

| Grinding Method | Accuracy | Time | Tool Life | Consistency |

| Manual/Improvised Grinding | Low | High | Reduced | Unstable |

| Cutter Grinder Machine | High | Lower | Improved | Stable |

This table is the real story. Cutter grinder machines bring control and repeatability to tool sharpening, which is what industrial grinding work needs.

The Role of Cutter Grinder Machine in Tool Rooms

Tool rooms are where precision matters most. In tool rooms, cutters are not just used—they’re maintained like assets. A cutter grinder machine becomes essential for keeping tooling in top shape.

It supports:

- Sharpening schedules

- Tool geometry correction

- Regrinding damaged edges

- Maintaining tool inventory value

This is one reason why tool rooms often invest early in cutter grinding solutions.

Why Maintenance Teams Value Cutter Grinder Machines

Maintenance teams don’t like emergency breakdowns. Nobody does. But cutter-related breakdowns are common in machining. Dull tools lead to poor cutting. Poor cutting leads to vibration. Vibration leads to machine wear. A cutter grinder machine helps maintenance teams keep tools sharp and avoid production issues before they happen. It’s preventive maintenance in the smartest way.

How Ekta Industries Supports Industrial Grinding Needs

At Ekta Industries, we understand that industrial buyers don’t want fancy promises. They want practical results. As a trusted Cutter Grinder Machine Manufacturer, our focus stays on manufacturing-friendly performance. Strong build. Smooth operation. Stable grinding output. Practical design.

We also understand regional manufacturing requirements, which is why industries across the country prefer a reliable Cutter Grinder Machine Manufacturer In Gujarat and a dependable Cutter Grinder Machine Manufacturer in India. And yes, Ekta Industries is built around industrial trust. That’s the biggest asset.

Why Choose Us

Ekta Industries is chosen by industrial buyers for one simple reason — we build machines for real factory work, not just for display. As a trusted Cutter Grinder Machine Manufacturer, we focus on practical engineering that performs well during long shifts. Our machines are made for stable grinding, consistent tool sharpening, and smooth daily operation. No unnecessary complexity. Just solid performance.

Each machine is designed with durability, operator-friendly controls, and a manufacturing-ready structure. This helps industries reduce tool costs, improve machining accuracy, and keep production running without interruptions. And when customers choose Ekta Industries, they don’t just get a machine. They get strong build quality, reliable support, and equipment that meets industrial grinding needs.

Conclusion

The importance of a cutter grinder machine in industrial grinding work is simple. It saves tools. It improves accuracy. It reduces downtime. And it keeps production moving smoothly. In industries where cutters are used every single day, grinding isn’t a “secondary task.” It’s a performance requirement. If tools aren’t sharp, machining suffers. Quality drops. Rejection rises. And your operators end up wasting time adjusting instead of producing.

A reliable cutter grinder machine helps manufacturers keep cutters sharp, reduce rejection, and maintain consistent machining results. It also cuts down unnecessary tool replacement costs — because you’re restoring tools instead of replacing them repeatedly. For businesses that want stable production and long-term efficiency, investing in a cutter grinder machine isn’t just smart. It’s a practical move that supports real growth.

Want expert guidance on choosing the right cutter grinder machine for your industrial grinding needs? Call +91 85 303 44444 or email info@ektaindustries.co.in today.

Key Takeaways

- Cutter grinder machines help extend tool life and reduce overall tooling cost.

- Sharp cutters mean better machining accuracy and a cleaner surface finish.

- In-house grinding reduces dependency on outside services — and avoids delays.

- Proper grinding lowers machine load and reduces the risk of tool breakage.

- Ekta Industries delivers durable cutter grinder machines built for real industrial use.

FAQs

Why is a cutter grinder machine important in industrial grinding work?

Because blunt cutters don’t just slow the job down — they increase rejection, spoil surface finish, and raise tool costs. A cutter grinder machine helps you maintain tool life, machining accuracy, and steady production flow.

How do I choose the right Cutter Grinder Machine Manufacturer?

Look for a manufacturer that builds machines for real shop-floor use — durable structure, stable grinding, easy operation, and reliable service support. Anyone can sell a machine. Support matters later.

Why prefer a Cutter Grinder Machine Manufacturer in Gujarat?

Because local and regional support makes a difference. A trusted Cutter Grinder Machine Manufacturer in Gujarat can offer quicker service, easier coordination, and faster help when the machine is needed urgently.

Is buying from a Cutter Grinder Machine Manufacturer in India beneficial?

Yes. A reliable Cutter Grinder Machine Manufacturer in India understands Indian industrial conditions and usually provides better service availability, quicker spare support, and machines built for long working hours.