Fence demand never waits. Not for labour. Not for slow weaving. Not for manual cutting. If you’re in the fencing business, you already know this feeling. A contractor calls and wants chain link fencing urgently. A factory needs boundary fencing before the next shipment arrives. A government tender suddenly moves faster than expected. And right there, the real problem appears — chain link fencing production can become painfully slow when the machine isn’t built for speed.

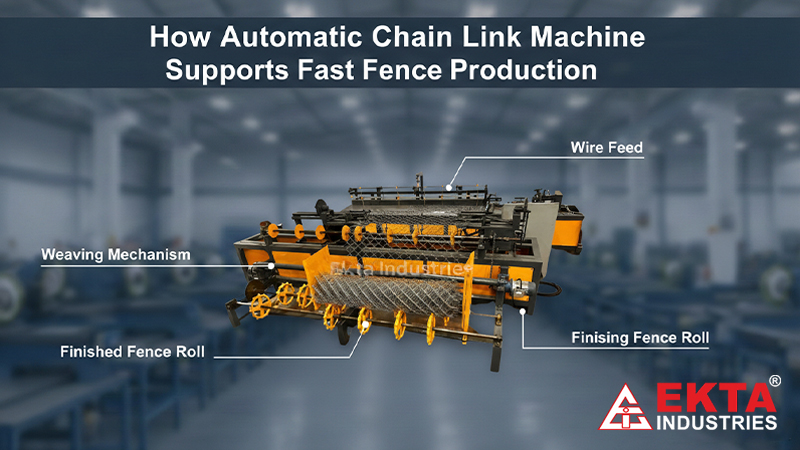

That’s why an Automatic Chain Link Machine matters. It’s not a “nice to have” upgrade. It’s the backbone of fast fence production. And when the machine is designed properly, it doesn’t just increase output. It improves the whole workflow — wire feeding, mesh weaving, edge finishing, cutting, and roll collection. Everything becomes smoother. More stable. Less waste.

In this blog, we’ll break down exactly how an automatic chain link machine supports fast fence production, what happens inside the process, what buyers should look for, and why choosing a trusted manufacturer like Ekta Industries changes the entire experience.

Understanding Chain Link Fencing Production

Chain link fencing looks simple when installed. A clean diamond pattern. Uniform mesh. Tight edges. A roll that unpacks smoothly and fits perfectly on site. But producing it? That’s a different story. Chain link fencing is made by twisting steel wire into continuous zig-zag patterns, interlocking each loop into the next, and forming a consistent mesh structure. This requires accurate wire tension, stable weaving speed, correct mesh size control, and consistent cutting length.

If any part of this is unstable, you get messy rolls, inconsistent mesh, broken wire, and production downtime. And in manufacturing, downtime is expensive. Sometimes it costs more than the machine itself over time. An automatic chain link machine solves these issues by turning the entire process into a controlled system rather than a manual struggle.

What Is an Automatic Chain Link Machine?

An Automatic Chain Link Machine is an industrial machine that converts wire into chain link mesh fencing automatically with minimal manual involvement. The machine typically handles wire feeding, weaving, mesh forming, and roll creation, based on selected settings. Instead of relying on manual weaving or semi-automatic operations, the machine maintains speed and uniformity through mechanical synchronization. This is what makes fast fence production possible.

A good automatic machine doesn’t only run faster. It runs cleaner. That’s the difference most people notice after installation. And this is where Ekta Industries comes in — building machines that are designed for production floors, not just for brochures.

Why Fence Production Speed Is a Business Advantage

Let’s be honest. Speed isn’t just speed. It’s money.

If your factory produces more fencing per shift, you can:

- Take bigger orders without stress

- Deliver faster, which builds client trust

- Reduce per-roll production cost

- Run fewer shifts for the same output

- Compete on pricing without killing margins

Fast production also gives you flexibility. If market demand changes, you can scale output quickly. If a big order lands suddenly, you don’t panic. You just run the machine. This is exactly why buyers look for a reliable Automatic Chain Link Machine Manufacturer instead of random suppliers.

How Automatic Chain Link Machines Make Production Faster

Speed doesn’t come from just increasing motor RPM. If you do that, the wire snaps, the mesh becomes uneven, and the machine starts vibrating like it wants to fly away. Real speed comes from stability. Smooth wire feeding. Controlled weaving. Consistent tension. Clean cutting. Here’s how an automatic chain link machine supports fast fence production in a practical way.

High-Speed Mesh Weaving with Stable Tension Control

Chain link weaving depends heavily on wire tension. Too tight and the wire breaks. Too loose and the diamonds become irregular. Automatic chain link machines are built to maintain steady tension across long runs. This keeps mesh size consistent and reduces rework. It also prevents the machine from slowing down due to frequent wire corrections. This is one of the biggest reasons productions becomes faster. They can just run the machine.

Consistent Diamond Size Without Constant Adjustments

In fencing, diamond size matters. It affects strength, appearance, and installation quality. Manual and low-grade machines often produce mesh where diamonds slowly drift out of size due to uneven wire feed or poor alignment. That leads to rejected rolls. Or worse, rolls that customers return. Automatic machines maintain consistent diamond geometry because the weaving mechanism is synchronized. Once you set the mesh size, the machine keeps it steady. That’s fast production without sacrificing quality. That’s the sweet spot.

Faster Roll Formation and Cleaner Output

Fast production is useless if roll formation is messy. A roll that doesn’t pack properly becomes a nightmare during transport and installation. Automatic chain link machines support faster roll production by forming the mesh into rolls smoothly. It reduces tangling and makes the roll edges more aligned. This also reduces labour at the end of the line. Workers spend less time tying, correcting, and re-rolling. And yes, that saves hours every week.

Smooth Wire Feeding That Reduces Breakage

Wire breakage is one of the biggest reasons chain link productions slows down. Each break forces the operator to stop, rethread, reconnect, and restart. Automatic machines support fast fence production by feeding wire smoothly. This reduces sudden jerks and uneven pull that causes breaks. A high-quality machine from Ekta Industries is designed to handle continuous production cycles with minimal interruption, which is exactly what a fencing business needs.

Faster Changeover Between Different Mesh Sizes

A factory rarely produces only one mesh size. Different customers want different fence specs. Some want tighter diamonds. Some want bigger openings. Some want different roll widths. An automatic chain link machine supports faster production by making these changeovers easier. When the machine is designed well, settings adjustments are simpler and more repeatable. That means less downtime. More production. More orders delivered.

Where Automatic Machines Help Most: Real Fence Use Cases

Chain link fencing isn’t used in one place only. It’s everywhere. That’s why demand stays high. Automatic chain link machines support fast fence production for industries like:

- Industrial boundary fencing for factories and warehouses

- Residential fencing for housing projects

- Sports ground fencing

- Highway and road fencing

- Farm fencing

- School and institutional fencing

- Temporary site fencing for construction

When demand comes from multiple sectors, speed becomes a survival tool. And automatic machines are built for that.

The Role of Automation in Reducing Labour Dependency

Here’s a reality many factory owners don’t say loudly: skilled labour is harder to find than before. Training new operators takes time. Skilled workers shift jobs quickly. And manual chain link production heavily depends on experience. Automatic chain link machines reduce that dependency. Operators still matter, of course. But the machine handles the technical consistency. This means production continues even if your most experienced worker is absent. And for long-term factory planning, that’s a big advantage.

Why Machine Build Quality Decides Speed Over the Years

Many buyers think speed is only about “how fast the machine runs today.” But speed after 6 months? After 2 years? That’s where build quality decides everything. Low-quality machines start slowing down because of:

- Gear wear

- Bearing issues

- Vibration problems

- Misalignment

- Frequent part replacements

- Motor overheating

A machine that runs fast today but breaks tomorrow is not fast. It’s expensive. That’s why buyers search for an Automatic Chain Link Machine Manufacturer In India that builds machines for industrial reliability, not just for low price tags.

Key Features That Support Faster Fence Production (What Buyers Should Look For)

If you’re planning to buy an automatic chain link machine, here are the most practical features that directly affect speed and output. This isn’t a checklist. It’s what impacts your daily production.

- Strong Weaving Mechanism with Stable Output: The weaving mechanism is the heart of the machine. If it’s weak, you’ll face irregular mesh, vibration, and breakdowns. A strong weaving mechanism supports higher speed without losing mesh consistency.

- Reliable Cutting System for Accurate Roll Lengths: Fast production also depends on accurate cutting. If rolls are cut unevenly, it creates wastage and customer complaints. A good machine cuts cleanly and consistently.

- Easy Controls for Operators: If operators struggle to control the machine, speed suffers. Machines should have simple, practical controls that allow quick adjustments without confusion. When machines are operator-friendly, production becomes faster naturally.

- Durable Components That Handle Continuous Shifts: A chain link machine often runs long shifts. Sometimes double shifts. Sometimes nonstop. Durable components support fast production because they reduce stoppages. Simple as that.

How Ekta Industries Supports Faster Fence Production

When you buy from Ekta Industries, you aren’t only buying a machine. You’re buying production stability. And stability is what makes speed possible. Ekta Industries focuses on industrial-grade manufacturing, practical machine design, and reliable output for real production floors. Their automatic chain link machine is built to handle consistent weaving, smooth operation, and long working hours. And because Ekta Industries operates as a trusted Automatic Chain Link Machine Manufacturer, they understand what fence manufacturers actually need: consistent mesh, less downtime, better control, and a machine that doesn’t demand constant repairs.

Choosing the Right Manufacturer Is the Real Decision

This is where most buyers make mistakes. They compare only price. Or they compare only speed claims. But they ignore the manufacturer. A machine is only as good as the company behind it. If spare parts, support, guidance, and machine knowledge are missing, you’ll struggle. That’s why businesses prefer working with an experienced Automatic Chain Link Machine Manufacturer in India who understands production realities, not just sales.

Why Choose Us

Ekta Industries stands out because we build machines that match real industrial expectations, not unrealistic promises. As a reliable Automatic Chain Link Machine Manufacturer, we focus on strong machine build, stable weaving, and long-term performance so your fence production stays smooth day after day. Our machines are trusted by manufacturers who need consistent output, cleaner rolls, and fewer stoppages. Based in Rajkot, we also serve as a recognized Automatic Chain Link Machine Manufacturer In Rajkot-based Automatic Chain Link Machine Manufacturer in Gujarat, supplying machines across India with practical support and real manufacturing expertise that makes buying simple and production faster.

Conclusion

An automatic chain link machine is one of the smartest upgrades for any fencing manufacturer who wants faster production without sacrificing mesh quality. It improves weaving speed, reduces wire breakage, keeps diamond size consistent, and produces cleaner rolls that customers can install easily. The real benefit is not just speed, it’s stability. When production runs smoothly, your factory can deliver bigger orders, meet deadlines, and grow with confidence. With the right machine and the right manufacturer like Ekta Industries, fast fence production becomes a daily routine, not a daily struggle.

Want faster fence production with a reliable automatic chain link machine? Call +91 85 303 44444 or email info@ektaindustries.co.in for expert guidance and product details.

Key Takeaways

- Automatic chain link machines increase fence output by stabilizing weaving and wire feeding.

- Consistent diamond size improves roll quality and reduces customer complaints.

- Smooth wire feeding reduces breakage and saves hours of downtime weekly.

- Build quality decides speed not just today, but after years of production.

- Choosing Ekta Industries supports long-term, stable, and fast fence manufacturing.

FAQs

How does an automatic chain-link machine improve fence production speed?

It reduces manual work, maintains steady wire tension, and runs continuous weaving cycles which cuts stoppages and increases daily output.

Why should I buy from an Automatic Chain Link Machine Manufacturer In Rajkot?

Rajkot is a major industrial manufacturing hub, and manufacturers here have strong expertise in machine building, tooling, and long-term support.

Is an Automatic Chain Link Machine Manufacturer in Gujarat better for support?

Yes, buying from Gujarat-based manufacturers often makes spare parts and service support quicker and more accessible across India.

How do I choose the right Automatic Chain Link Machine Manufacturer in India?

Look for proven experience, machine build quality, stable output performance, and strong after-sales support, not just price and speed claims.